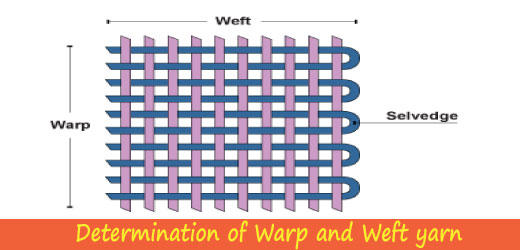

Weft: The horizontal yarns are called weft yarns.Taking up: winding newly formed cloth onto the cloth beam, Letting off: releasing yarn from a warp beam.Beating up: packing the weft yarn into the cloth to make it compact.Picking: inserting of weft yarn by the shuttle through the shed.Shedding: raising and lowering of warp yarns by means of the harness to form shed, opening between warp yarns through which weft yarn passes.

WARP AND WEFT SERIES

The loom goes through a series of motions The warp yarns are conveyed to a cylinder called the cloth beam which is in front. Once the filling yarns have been prepared and the warp beam containing the sized yarns is placed at the back of the loom. Basic Weaving Operation – 4 basic steps Primary Motions Yarn that is to be used for filling must be packaged in some form that allows it to be unwound easily for transport through the shed is called a shuttle and is made up of a wooden carrier into which a quill or pirn is placed. The number of harnesses required for the loom is determined by the weave. Heddle wires are held in frames called harnesses. Placing the warp yarns on the loom is done either by drawing-in or by tying-in. The Drop wire is a device that will stop the loom if an end should break, the heddle eye is the opening in a heddle that carries the yarn, and the reed comb-like device that will push each filling yarn close against the completed fabric. In preparation for weaving, each warp end (yarn) must be threaded through its own drop wire, heddle eye, and reed dent. Before their use on the loom, warp and filling yarns must be prepared for weaving.

0 kommentar(er)

0 kommentar(er)